Balance Shafts are Commonly Used in Conventional 4-Cylinder Engines To ________.

Balance shafts are commonly used in conventional 4-cylinder engines to enhance engine smoothness and reduce vibrations. These rotating components work in tandem with the crankshaft to counteract the inherent imbalance caused by the reciprocating motion of pistons. By adding a secondary shaft with offset weights, balance shafts help mitigate unwanted vibrations that can negatively impact engine performance and passenger comfort.

The primary purpose of balance shafts is to improve engine refinement and reduce noise, vibration, and harshness (NVH) levels. The counterweights on the balance shafts create an opposing force that cancels out the unbalanced forces generated by the pistons during their up-and-down movement. This balancing action ensures smoother operation by minimizing any excessive shaking or rattling within the engine.

The Evolution of Engine Balancing Technology

Over the years, advancements in technology have led to the evolution of engine balancing techniques. Manufacturers have continuously strived to find innovative solutions to address engine vibrations more effectively. One notable trend is the development of dual-mass flywheels, which provide enhanced rotational balance by separating the crankshaft from the clutch assembly. This design helps minimize unwanted vibrations transmitted to the drivetrain.

Additionally, advanced computer modeling and simulation tools have revolutionized the process of balancing engines. With these tools, engineers can accurately predict and analyze potential vibrations throughout different operating conditions. This enables them to optimize balance shaft designs for specific engines, resulting in improved performance and smoother operation.

New Approaches to Engine Vibration Control

In recent years, there has been a shift towards adopting active vibration control systems as an alternative or complement to conventional balance shafts. These systems use sensors and actuators strategically placed within the engine to actively counteract vibrations in real-time. By monitoring various parameters such as speed, load, and temperature, these systems adjust their response accordingly to achieve optimal balance.

One example of this technology is active motor mounts that can actively change stiffness based on detected vibrations. These motor mounts adaptively dampen vibrations by altering their characteristics according to changing conditions during engine operation.

Benefits of Using Balance Shafts

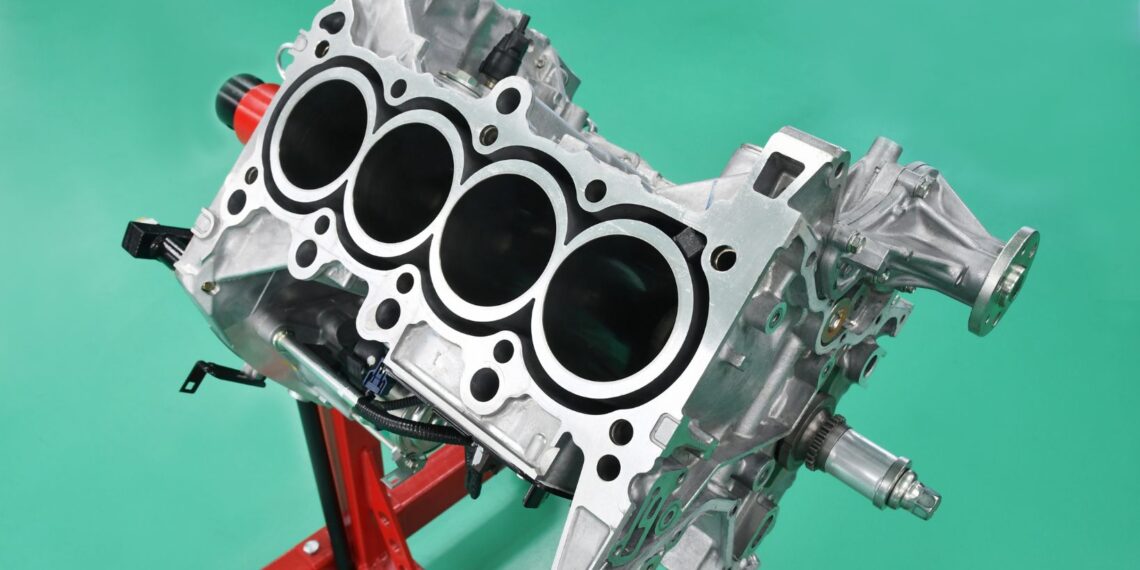

When it comes to conventional 4-cylinder engines, balance shafts are commonly used to enhance their performance and reduce vibrations. In this section, we’ll explore the benefits of incorporating balance shafts into these engines.

One significant advantage of using balance shafts is the improvement in engine smoothness. These specialized components help counteract the inherent imbalance caused by the reciprocating motion of pistons. By adding an additional rotating mass that spins in the opposite direction of the crankshaft, balance shafts effectively counterbalance the vibrations and forces generated during engine operation.

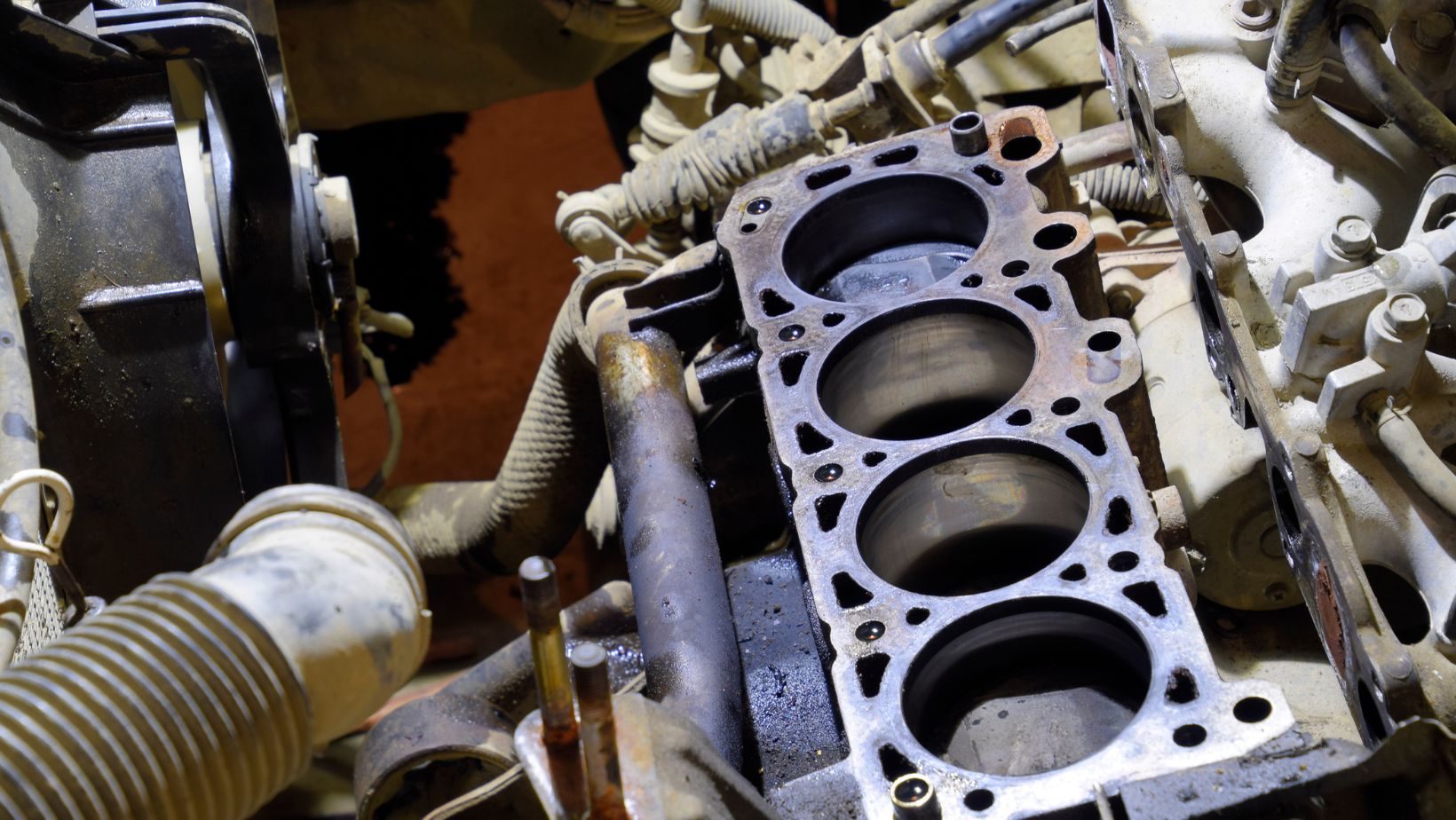

By mitigating vibrations within a 4-cylinder engine, balance shafts contribute to a smoother overall driving experience. The presence of excessive vibrations can lead to increased noise levels and discomfort for both drivers and passengers. With balance shafts in place, these unpleasant effects are significantly reduced, resulting in a quieter cabin and smoother ride quality.

The use of balance shafts also contributes to improved durability and reliability of 4-cylinder engines. Excessive vibrations can put unnecessary stress on various engine components, potentially leading to premature wear or failure over time. By minimizing these vibrations, balance shafts help ensure that crucial parts such as bearings, crankshafts, and connecting rods operate within their intended design parameters. This ultimately leads to enhanced longevity and reliability for the engine as a whole.

In conclusion, incorporating balance shafts into conventional 4-cylinder engines offers several benefits. It improves engine smoothness by counterbalancing inherent imbalances caused by piston motion. Additionally, it reduces vibrations and noise levels inside the vehicle cabin for a more comfortable driving experience.